Project specifications are not often considered the most glamorous part of an architectural project, but they are an effective tool for tackling reductions in embodied carbon in materials. Reducing embodied carbon directly supports our recent signing of the AIA Materials Pledge by prioritizing low-carbon materials and requiring material transparency.

At Amenta Emma, we have embarked on a task to update our specifications to:

- prioritize materials that have lower embodied carbon

- promote material transparency through requiring Environmental Product Declarations (EPD)

We kicked off this effort by identifying two high-impact materials where we would make measurable impacts: concrete and insulation.

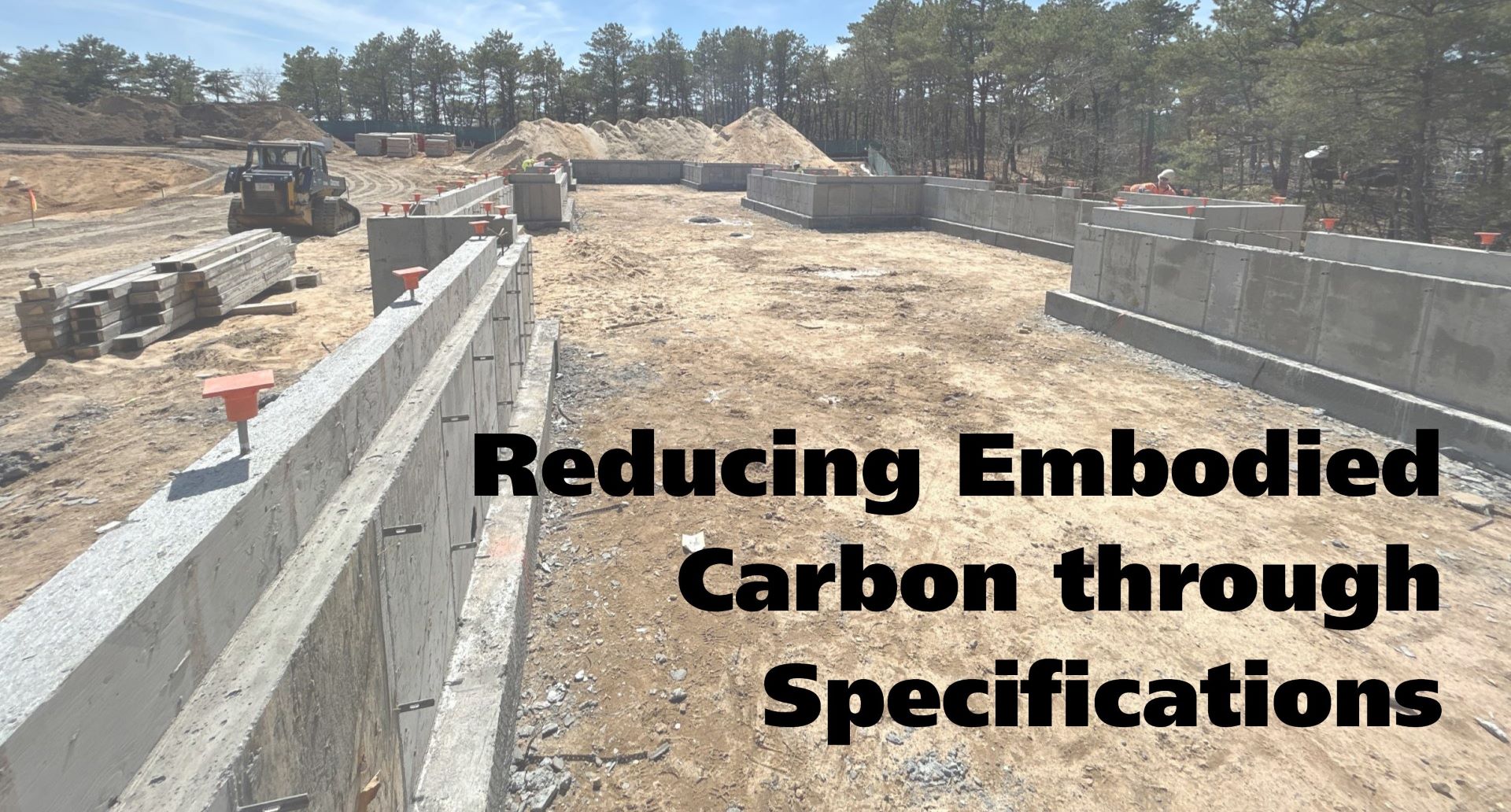

Concrete

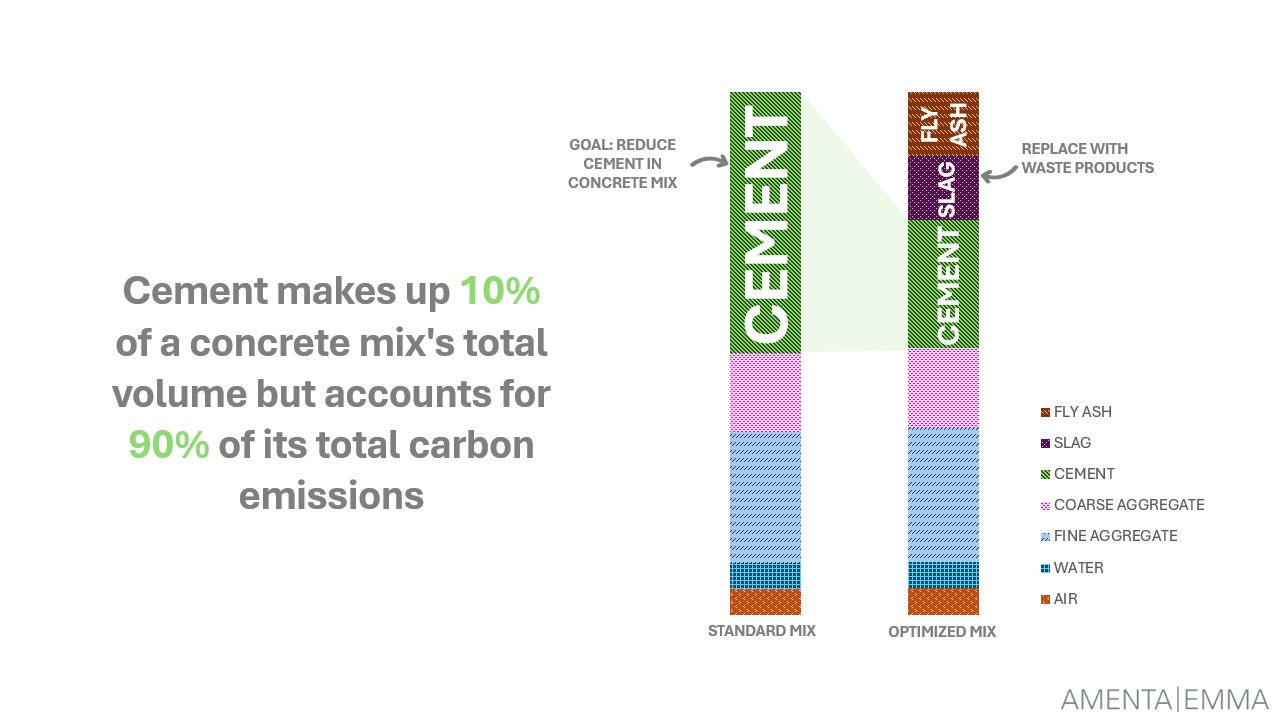

Concrete is a critical material to address if we are going to reduce the embodied carbon impacts of our projects. The main source of embodied carbon in concrete is the cement, which is the binder that gives concrete its strength. Cement production accounts for roughly 6-7% of the world’s CO2 emissions. Through our research, we have updated our standard specifications to target a 20% reduction in global warming potential (GWP) across all cast-in-place concrete on our projects. This is achieved by moving towards performance-based requirements that require concrete suppliers to meet the project’s structural requirements while affording them flexibility to replace cement with supplementary cementitious materials (SCM) such as slag or fly ash. This strategy is in line with guidelines published by the National Ready Mixed Concrete Association (NRMCA) and the Boston Society of Architects’ Low Carbon Concrete Initiative. We will continue to reevaluate and push our carbon reduction targets further as new and innovative solutions, such as glass pozzolans, electric manufactured cement, and carbon sequestering aggregates, are developed and come to the market.

Insulation

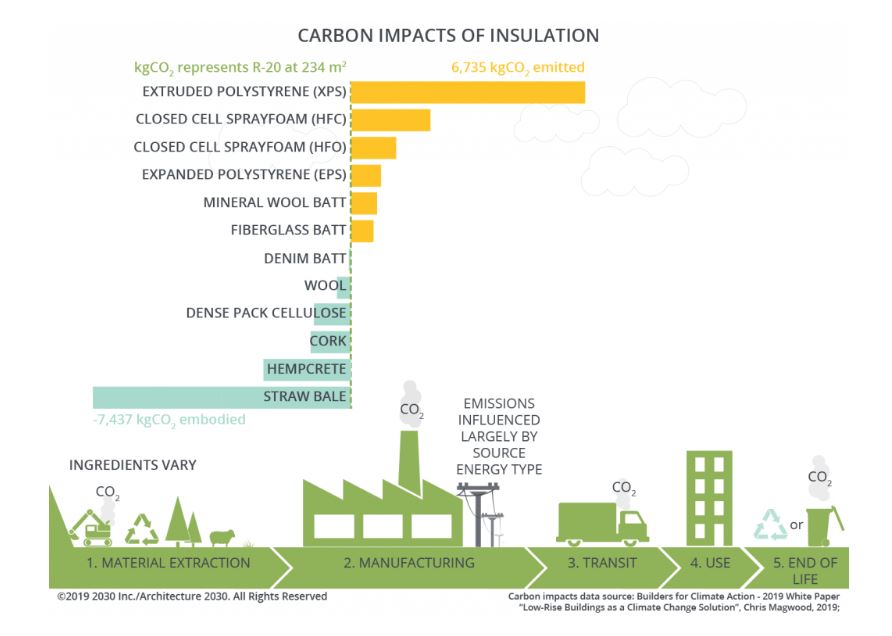

Within insulation, we targeted extruded polystyrene (XPS) insulation first as it had the largest carbon footprint of any insulation by far. Fortunately, multiple established manufacturers have already begun to bring low-carbon XPS options to the market, and in some cases have begun to phase out the older carbon-intensive offerings. After confirming these new low-carbon options met all the other performance requirements of our specification, we were able to update our standard specification to the low-carbon XPS as the basis of design. This simple spec change will result in a 75% reduction in global warming potential (GWP) from XPS insulation on all our projects moving forward.

Immediate Results

Our Community Studio issued bid documents for the Meadow Gardens affordable housing development in Norwalk, CT, in November 2024, shortly before our new concrete specification was approved internally. This development has over 6,000 cubic yards of cast-in-place concrete due to the topography of the project site. Once the specification was approved, the project team immediately shared it with the structural engineer, civil engineer, and construction manager so it could be implemented into the bid documents. In the end, the new specification was accepted with no additional cost to the project. The reduction in GWP on this project alone is equivalent to 7,000 round trips between our Hartford and Boston offices.