3-Part Series

In a recent blog post, we introduced readers to a new construction method using mass timber, and we covered some concerns raised during our public presentations over the Bushnell South residential development in downtown Hartford. The questions of ‘why mass timber?’ and ‘is it safe?’ were addressed early in the design process. As we dug deeper into this construction method and really began to understand it, we uncovered some unexpected benefits.

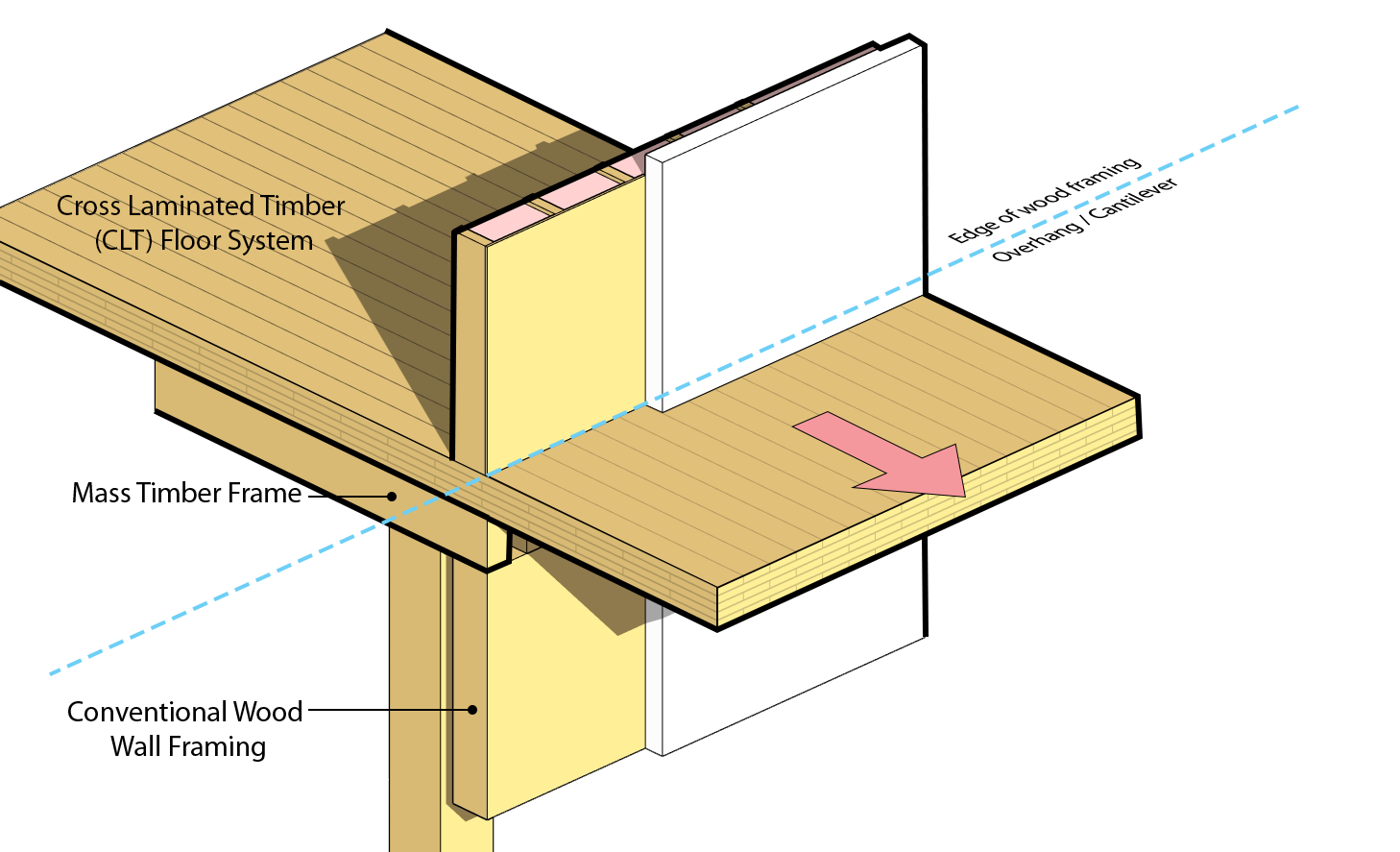

The structure we are proposing for Bushnell South is comprised of a mass timber frame combined with a cross laminated timber flooring system. Mass timbers are solid wood, load-bearing components that are manufactured by adhering many smaller pieces of lumber together to achieve the engineering requirements. Cross laminated timber, or CLT for short, is engineered solid wood panels that can serve as load-bearing walls or floor systems. The panels are created by alternating the direction of the lumber 90 degrees from the layer below it (think plywood at a much larger scale). These create elements that are dimensionally stable and able to span much further than individual members.

Taller Building

The conventionally wood-framed building has dominated the low-rise multi-family sector for years; our portfolio has its fair share. But this construction type is limited to five stories of wood construction, and even then, there are requirements for special detailing and fire treating that add cost. Special code considerations have been given to include concrete for the first two stories, allowing these structures to climb to seven total stories, but concrete can add time to the schedule, and the interaction between the materials requires special attention. Because of its inherent fire rating, the mass timber frame is recognized by the building code as a different construction type, which, under the right circumstances is permitted to achieve 18 stories of height, much taller than a conventionally framed building.

By using a CLT flooring system in our Bushnell South project, we saw a reduction of more than nine feet of exterior finishes.

Reduced Height

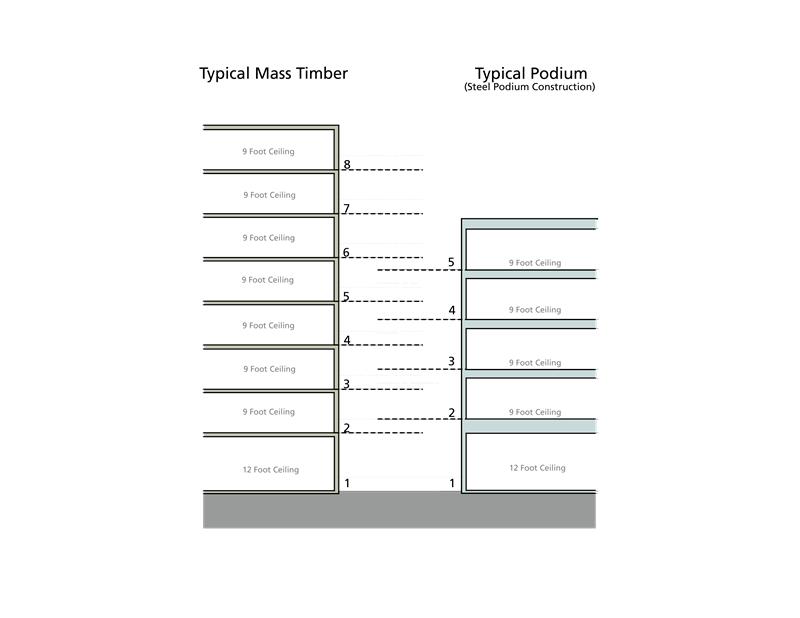

In conventionally framed buildings, the assembly for floor framing typically works out to around 2 feet, incorporating trusses and finishes top and bottom. A CLT flooring system reduces this assembly to less than 10 inches. At first glance, a 14-inch reduction may not seem like much, but this adds up significantly as the number of stories increases. With eight stories, we saw a reduction of more than nine feet of exterior finishes. Additionally, our eight-story building at Bushnell South is able to come in below the high-rise building threshold outlined in the building code, while maintaining nine-foot ceilings in the units.

Cantilevers

This is a word that makes architects grin with joy and sends engineers running for the hills. The CLT floor system offers relief for both. Because they operate as a more complex structural system than trusses, we are able to take advantage of this and cantilever the panels in both the strong and weak direction. At Bushnell South, we were able to cantilever four feet out from our exterior columns without adjusting any framing or incurring any additional cost.

Mass Timber cantilever diagram – Bushnell South, Hartford, CT

Biophilia

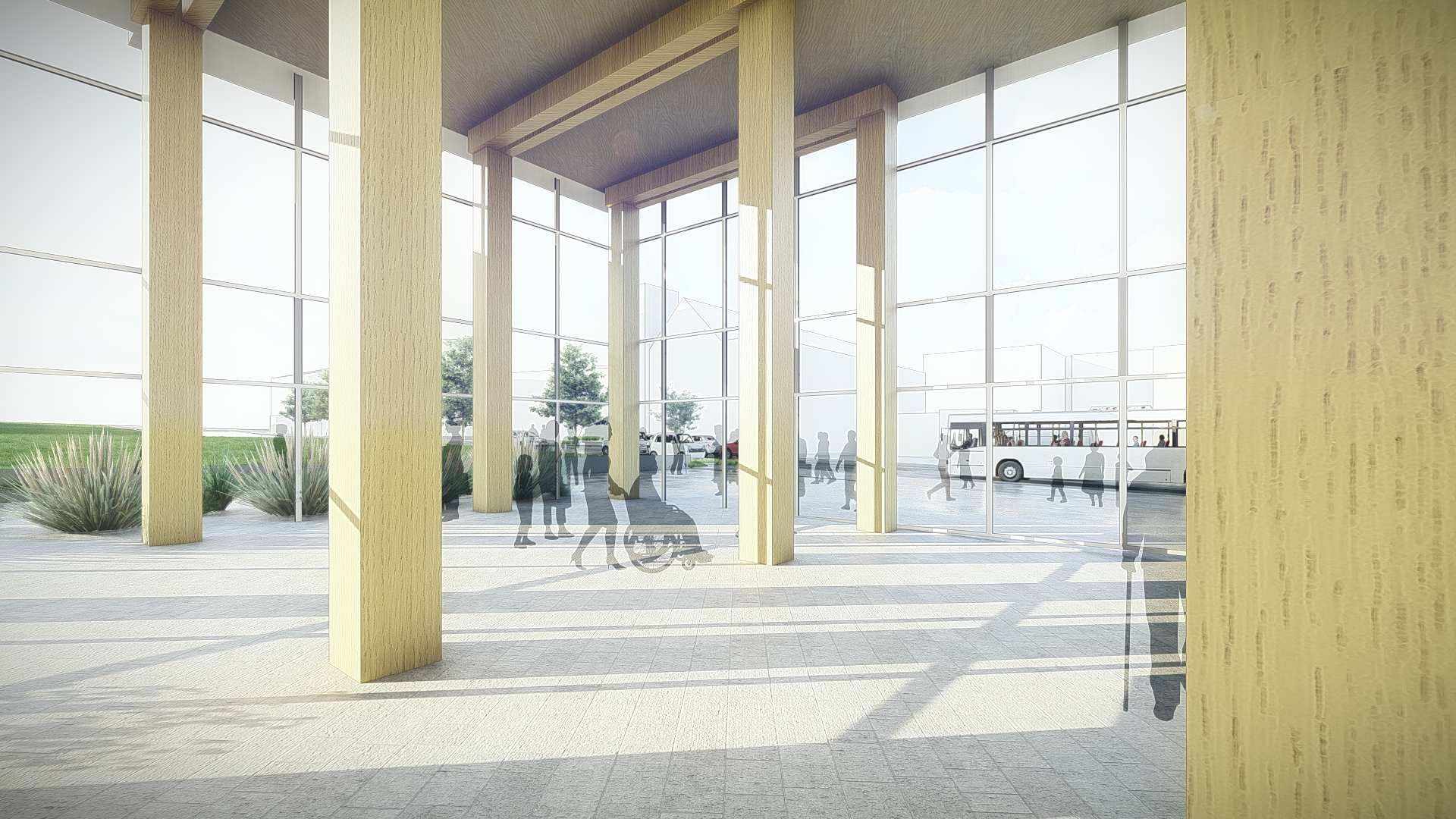

Human beings have a desire to connect with the natural environment. To accomplish this, we typically introduce natural materials in our interior spaces – these can be living walls, wood ceilings or even a water feature. Since the mass timber and CLT frame we proposed meet the code required ratings, all the structural elements can remain exposed to the interior of the building. Columns, beams, and ceilings bring the warmth of natural wood into each of the occupied spaces in the building with no additional cost.

The warmth of the natural wood columns and beams introduce an element of nature to occupied spaces at no additional cost.

Is there a downside?

Are there any drawbacks to the mass timber construction method? Yes. In the final mass timber blog post, we will address common drawbacks and a few that surprised us along the way.